Hey there! I’ve been freeze-drying at home for about eight years, and it’s a fascinating process.

Freeze drying is a way to remove moisture from substances while keeping their biological and chemical structures intact so that food maintains its nutritional value and texture. It’s great for preserving food, pharmaceuticals, and other substances without damaging their quality.

The process works by sublimation, which means turning ice directly into vapor without going through the liquid phase. It’s an effective way to remove water without messing up the substance’s structure, making it a valuable tool in many industries.

In this article, I’d love to share my knowledge, experiences, and failures with you as an overview of freeze-drying and as a hub linking to all of my other related information on this website.

Table of Contents

What is Freeze-Drying?

Freeze-drying is a way to remove water (or ice) from frozen objects in a vacuum chamber via processes called lyophilization and sublimation. Freeze-dried objects are lighter, have a long shelf-life, and can be easily stored for long periods.

How Does Freeze Drying Work?

Freeze drying, also known as lyophilization, is a low-temperature dehydration process that involves freezing the product and lowering the pressure, eventually removing the ice content by sublimation (turning a solid like ice directly into a gas, skipping the liquid phase).

When you put trays of food in a freeze dryer’s chamber, the machine quickly freezes the food to temperatures between -30° and -50°F (-34° and -45°C) or lower. Next, the freeze dryer pulls the air out of the chamber, and the trays are slightly heated. As the food heats, the water sublimates, directly converting the ice from solid to vapor without going through a liquid phase.

How freeze drying works is this: it freezes the food and sucks the water out in a vacuum chamber by instantly changing the ice to vapor when it slowly heats up. That’s how I explained it to my kids, and they got it. Simplified? Yes, definitely. But it gets the point across.

Steps of the Freeze Drying Process

Freeze drying generally consists of three main steps: freezing, primary drying, and then secondary drying.

Let me guide you through these stages and highlight some key information.

Primary Drying

In the primary drying phase, the goal is to remove most water from the freeze-dried material. This is done by applying a low temperature and vacuum to the sample.

The water in the sample forms ice crystals that are then sublimated, shifting from solid directly into gas. As a result, the water content leaves the sample without passing through the liquid phase.

Maintaining low temperatures is essential to prevent the sample from melting. Also, keeping the environment under a vacuum allows the water molecules to escape more easily, ensuring a more efficient drying process.

Secondary Drying

After primary drying has removed most of the water, it’s time for secondary drying. In this stage, the temperature gradually increases while maintaining a vacuum. This helps remove any remaining bound water molecules from the sample.

An important aspect of secondary drying is to avoid damaging the sample by increasing the temperature too quickly. Instead, it’s best to use a controlled heating process to remove any residual moisture without harming the integrity of the sample.

Throughout the entire freeze-drying process, it’s crucial to maintain proper temperature and vacuum conditions to ensure the best results. By achieving an optimal balance, it’s possible to preserve the characteristics of the original material, making freeze-drying an invaluable method in a wide range of industries.

The Equipment Used for Freeze Drying

There are three essential pieces of equipment commonly used in freeze-drying:

- The freeze dryer,

- A vacuum pump,

- And the vacuum chamber.

If you want more equipment specific information on freeze dryers, make sure you read this article.

Otherwise, the only other thing you need to know is that Harvest Right is the leading brand for home-based and cottage business freeze-drying equipment.

Small Pro

from $2,695

Rating: ⭐⭐⭐⭐⭐ 4.6

Best for small families

More Details

- 4 Trays

- 6-10 pounds of food per batch

- Best for small families of 1-4 people

- Add $1,495 to upgrade to oil-free pump

Medium Pro

from $3,195

Rating: ⭐⭐⭐⭐⭐ 4.9

Best for most families

More Details

- 5 Trays

- 10-15 pounds of food per batch

- Best for most families

- Add $1,495 to upgrade to oil-free pump

Large Pro

from $3,795

Rating: ⭐⭐⭐⭐⭐ 4.7

Best for food storage pros

More Details

- 6 Trays

- 18-27 pounds of food per batch

- Best for large families or food storage pros

- Add $1,495 to upgrade to an oil-free pump

- Requires a dedicated 20-amp circuit

X-Large Pro

from $5,295

Rating: ⭐⭐⭐⭐⭐ 4.8

Best for food businesses

More Details

- 7 Trays

- 40-50 pounds of food per batch

- Best for large families or cottage businesses

- Comes with XL Premier Industrial Pump

- Add $1,695 to upgrade to an XL oil-free pump

- Requires a dedicated 20-amp circuit

If you click a link and make a purchase, we earn a commission at no additional cost to you. Full disclaimer information is in our terms and conditions.

Freeze Drying: Running a freeze dryer

It’s essential to know how to monitor and control the freeze-drying unit (including the vacuum chamber and pump) to properly freeze-dry items so they are safe for eating in the future.

- If you build a DIY freeze-dryer, you must know these concepts backward and forward to complete the job.

- If you get a Harvest Right freeze-dryer, you can manage these primarily by watching the drying time and overall chamber temperature.

Temperature and pressure control are crucial in freeze-drying for maintaining product quality. Monitoring product temperature optimizes drying speed and prevents damage to the product structure by keeping it below a specific limit.

Pressure management is also essential, and monitoring devices like thermocouples, pressure measurement, and vacuum shut-off valves help keep levels within the desired range for a successful freeze-drying process.

Unexpected problems can arise during freeze-drying, but monitoring drying time and temperature can help troubleshoot issues. Annealing, a controlled heating process, can optimize drying time by improving ice crystal structure. Close monitoring enables quick corrective action, ensuring batch integrity and product quality.

Again, for more detailed information on freeze-dryer units, read our main article here, which will take you to anything and everything you’d want to know about freeze-dryers.

Freeze Drying Food and its Benefits

Freeze-drying is the only way to create shelf-stable food storage lasting up to 25 years or more. Freeze-dried foods maintain up to 98% of their original nutrients and keep their original texture and shape, making it easy to reconstitute and use the foods in the future.

As a food lover, I’ve always been fascinated by different food preservation methods. One technique that I find particularly interesting is freeze-drying. In this section, I’ll discuss the benefits of freeze-drying foods, including fruits and vegetables, meats, dairy, and grains. I’ll also talk about the taste and flavor of freeze-dried foods.

If you’d rather read exactly which nutrients are maintained during freeze-drying, read my article: Does Freeze-Drying Foods Kill It? (Bacteria, Virus, Nutrients, Enzymes).

Freeze Drying Fruits and Vegetables

When it comes to preserving fruits and vegetables, freeze-drying is an excellent option. The process retains most of its nutrients and original flavor. When I freeze-dry fruits like strawberries or apples, their vibrant colors and natural sweetness remain mostly unchanged. Freeze-dried vegetables like peas or carrots also retain a pleasant crunch and fresh taste.

Freeze-drying fruits and vegetables are probably my favorite part of freeze-drying food at home. Freeze drying potatoes is another option.

Meats

Freeze-drying also works well for preserving meats. It can extend the shelf life of meats like chicken, beef, and fish. I love that freeze-dried meats easily rehydrate (or reconstitute), making them perfect for camping trips or emergency food kits.

Dairy and Grains

Dairy products such as milk, cheese, and yogurt can also be freeze-dried. I’ve found that freeze-dried milk and yogurt taste almost as good as their fresh counterparts. They’re especially convenient for traveling or when refrigeration isn’t available.

Grains, like rice, pasta, and bread, can be freeze-dried for long-term storage, retaining their taste and texture. Freeze-drying parboiled grains make a great alternative to 1-minute boxes of rice.

The Taste and Flavor of Freeze-Dried Foods

One of the most appealing aspects of freeze-dried foods is their taste and flavor. Since the freeze-drying process removes water without exposing foods to high temperatures, it preserves their natural flavors.

In my experience, eating properly rehydrated freeze-dried food is almost like enjoying a freshly prepared meal. If you rehydrate the food properly, you won’t be able to tell the difference. It’s only if you get impatient that you’d ever notice a difference.

So, freeze-drying is a versatile and effective food preservation method for fruits, vegetables, meats, dairy, and grains. Give it a try and taste the difference it makes!

How to Store Freeze-Dried Foods

Freeze-dried foods should ideally be stored in a cool, dry location that has light, humidity, and temperature control. Food should be stored in an airtight container (like Mylar) with an oxygen absorber. This will maximize the safety of the food and extend its potential shelf-life to the utmost.

Once you’ve finished freeze-drying food, ensure it’s properly done before storing it for the long term. If you need help with any how-tos or want some extra tips to ensure it’s properly freeze-dried without having to do a ton of work, bookmark our freeze drying how to: How to Freeze Dry and Store Your Favorite Foods: Guide with Pictures.

Proper Storage Procedures

Admittedly, storing freeze-dried foods can be a little tricky. Choosing an airtight container to keep moisture and oxygen out is important. I prefer using Mylar bags as they are durable, lightweight, and easy to seal. These bags are essential for long-term storage, and they come with an added benefit: you can easily write the date and food type on them.

When I pack my freeze-dried food, I like to add an oxygen absorber to the Mylar bag. It helps ensure that no oxygen is left in the bag, which could damage the food over time. Once the bag is sealed, I store it in a cool, dry, and temperature-controlled area. This helps to prevent any damage from sunlight or pests.

The Shelf Life of Freeze-Dried Foods

One of the best things about freeze-dried foods is their extended shelf life. These foods can last 25 years or even longer with proper storage! This is achieved by removing the moisture and oxygen content from the food, which inhibits the growth of microorganisms like molds.

To give you an idea of what to expect when storing freeze-dried foods, here’s a handy table with some notable examples:

| Food Item | Shelf Life |

|---|---|

| Freeze-dried fruits | 25 years |

| Freeze-dried vegetables | 25 years |

| Freeze-dried meats | up to 25 years |

Note that meats can be freeze-dried and stored for up to 25 years; the exact timeframe will depend on the cut of meat, how fatty it is, and if there are bones in it.

By following the proper storage procedures and understanding the shelf life of freeze-dried foods, I can confidently stock up on these items knowing that they will remain safe and nutritious for years.

Freeze Drying Options

Freeze-drying is used in the food industry (both at home and commercially) to preserve food items such as fruits, vegetables, and meat. Freeze-drying is also used in other commercial, industrial, and pharmaceutical endeavors to preserve and store items, drugs, and vaccines.

The process is beneficial because it preserves the nutritional value, flavor, and texture of the product while also extending its shelf life. Also, freeze-drying allows for easy transportation and storage of the product, making it a popular option for those needing to transport perishable items over long distances.

Freeze Drying at Home

Freeze drying food at home is perfect for preserving food, herbs, and other perishable items. Home freeze-drying allows me to have control over the entire process and gives me peace of mind knowing exactly what went into the preservation of my foods.

Is It Possible to Freeze Dry Without a Machine?

Though it’s challenging to replicate the precise conditions of a freeze dryer at home, it is possible to freeze dry food without a machine using a method called “sublimation.” This involves freezing the food and placing it in a vacuum-sealed bag to remove moisture.

However, sublimation is less effective than using a freeze-drying machine and may not produce the desired results.

In my experience, properly freeze-dried foods taste better and have a better texture than sublimated foods. Using freeze drying equipment is the only way to get

Best Freeze-Dryer Brands for Home Use

For home use, the #1 brand is Harvest Right. The size you’ll need depends on expected use, family size, and if you’ve got a dedicated 20-amp circuit available.

Small Pro

from $2,695

Rating: ⭐⭐⭐⭐⭐ 4.6

Best for small families

More Details

- 4 Trays

- 6-10 pounds of food per batch

- Best for small families of 1-4 people

- Add $1,495 to upgrade to oil-free pump

Medium Pro

from $3,195

Rating: ⭐⭐⭐⭐⭐ 4.9

Best for most families

More Details

- 5 Trays

- 10-15 pounds of food per batch

- Best for most families

- Add $1,495 to upgrade to oil-free pump

Large Pro

from $3,795

Rating: ⭐⭐⭐⭐⭐ 4.7

Best for food storage pros

More Details

- 6 Trays

- 18-27 pounds of food per batch

- Best for large families or food storage pros

- Add $1,495 to upgrade to an oil-free pump

- Requires a dedicated 20-amp circuit

X-Large Pro

from $5,295

Rating: ⭐⭐⭐⭐⭐ 4.8

Best for food businesses

More Details

- 7 Trays

- 40-50 pounds of food per batch

- Best for large families or cottage businesses

- Comes with XL Premier Industrial Pump

- Add $1,695 to upgrade to an XL oil-free pump

- Requires a dedicated 20-amp circuit

If you click a link and make a purchase, we earn a commission at no additional cost to you. Full disclaimer information is in our terms and conditions.

Commercial Freeze Drying

Commercial freeze-drying is suitable for businesses that want to preserve food on a larger scale. This option is often used in the preparation of freeze-dried meals for backpacking, camping, and emergency supplies.

The process is similar to home freeze drying, but the equipment and capacities can be larger, allowing for higher efficiency and larger quantities of food to be freeze-dried.

Harvest Right still tends to be the best value for cottage businesses, and they have both the Home Pro and the commercial lines to look at. They’re on the same line, from everything I can tell.

If you need to go a lot larger, other businesses sell much larger units, although the price is also higher.

Freeze Drying in the Food Industry

As a fan of preserving flavors and nutritional value in food products, I’ve become quite intrigued by freeze-drying in the food industry.

This section will discuss the industrial freeze-drying process and share some insights on consumer-ready freeze-dried products. Let’s dive right in.

Consumer-ready Freeze-Dried Products

Freeze-drying technology is an excellent solution for preserving a wide variety of food products, including meats, vegetables, fruits, and even micro-powders.

When it comes to consumer-ready freeze-dried products, I must say they have some distinct advantages over conventional fresh foods.

- Extended Shelf Life: Freeze-dried products can be stored longer than fresh foods, allowing you to stock up on your favorite items without worrying about spoilage.

- Retained Nutritional Value: Freeze-drying keeps the essential nutrients intact, ensuring you receive the same benefits as consuming fresh food.

- Lightweight and Portable: As the majority of the water content is removed, freeze-dried products become quite lightweight. This makes them ideal for camping trips, hiking, and emergency food supplies.

- Food Safety: Due to the absence of moisture, freeze-dried foods are less likely to harbor harmful bacteria, thus reducing the risk of foodborne illnesses.

Now that I’ve shared some facts about freeze-drying in the food industry, I hope this information has piqued your interest in this fascinating process and the benefits it offers for preserving food products.

Industrial Freeze Drying

Industrial freeze-drying plays a crucial role in the preservation of various materials beyond just food. It caters to high-capacity needs and is employed by the aerospace, biotechnology, and agriculture industries.

The primary purpose of industrial freeze drying is to make products more stable, easier to transport, and extend their shelf life. I understand that the technology and equipment used in industrial freeze-drying can be quite intricate, but it is ultimately reassuring to know that this method keeps sensitive items safe and usable for extended periods.

Most industrial freeze-dryers are priced too high for at-home use and too large to keep in a home.

Non-food Applications of Freeze Drying

There’s more to freeze-drying than just food preservation. I found that one interesting use of this technique is in taxidermy. It allows for the preservation of whole animal specimens and maintains their original appearance quite well.

Another application I came across is the restoration of water-damaged books and other objects. By carefully controlling the freeze-drying process, water can be removed without causing further damage to the affected items.

In research settings, freeze-drying is also useful for concentrating and recovering reaction products. This helps researchers to analyze their experiments more accurately and effectively.

It’s amazing how versatile the freeze-drying process is and how it can be applied to various industries and fields. Who knew something as simple as removing water from an object could have many practical uses?

Pharmaceutical Freeze Drying

Pharmaceutical freeze-drying is critical in the drug development and preservation process. It helps maintain the potency and integrity of active pharmaceutical ingredients (APIs), vaccines, and biopharmaceuticals, ensuring they remain effective when delivered to patients.

Pharmaceutical freeze-drying units come in all sizes and shapes, although they tend to be the most expensive.

Use in Pharmaceutical Industry

I discovered that freeze-drying is a popular technique in the pharmaceutical industry. This method became quite popular during World War II when it was used for preserving vital substances like penicillin and blood plasma.

The stability of these products was increased, making it easier to transport and store them, especially in difficult conditions on the battlefield. It’s fascinating to see how history influenced modern-day applications!

Freeze Drying Vs Other Food Preservation Options

Freeze drying is an excellent food preservation method that has become increasingly popular in recent years. This process involves removing moisture from food by freezing it and then placing it in a vacuum chamber where the frozen water is removed by sublimation, leaving behind a dry, lightweight product.

This method is particularly useful for preserving perishable foods such as fruits, vegetables, and meats, as well as for creating long-lasting emergency food supplies.

But how does it compare to other methods? Let’s look at it.

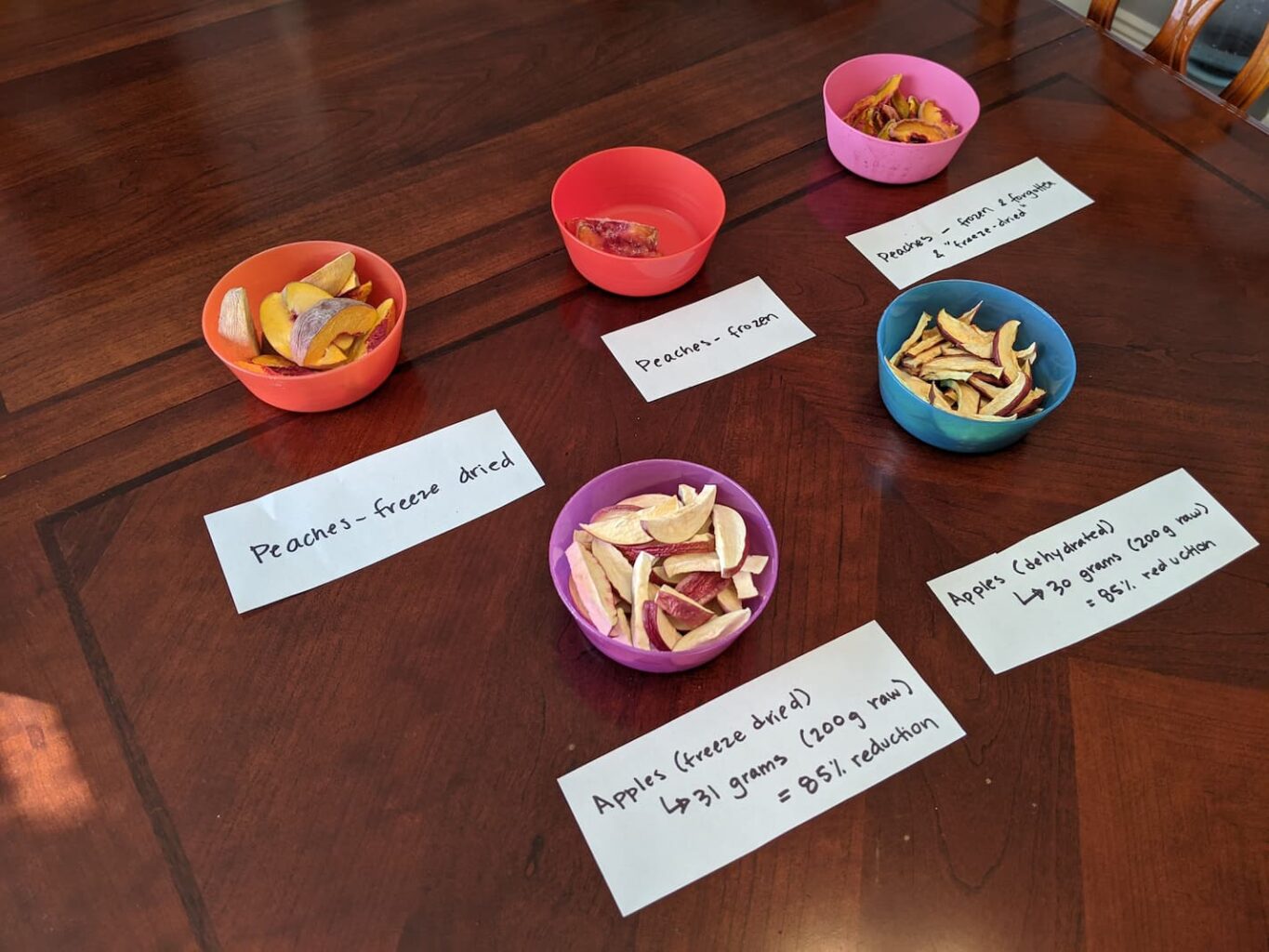

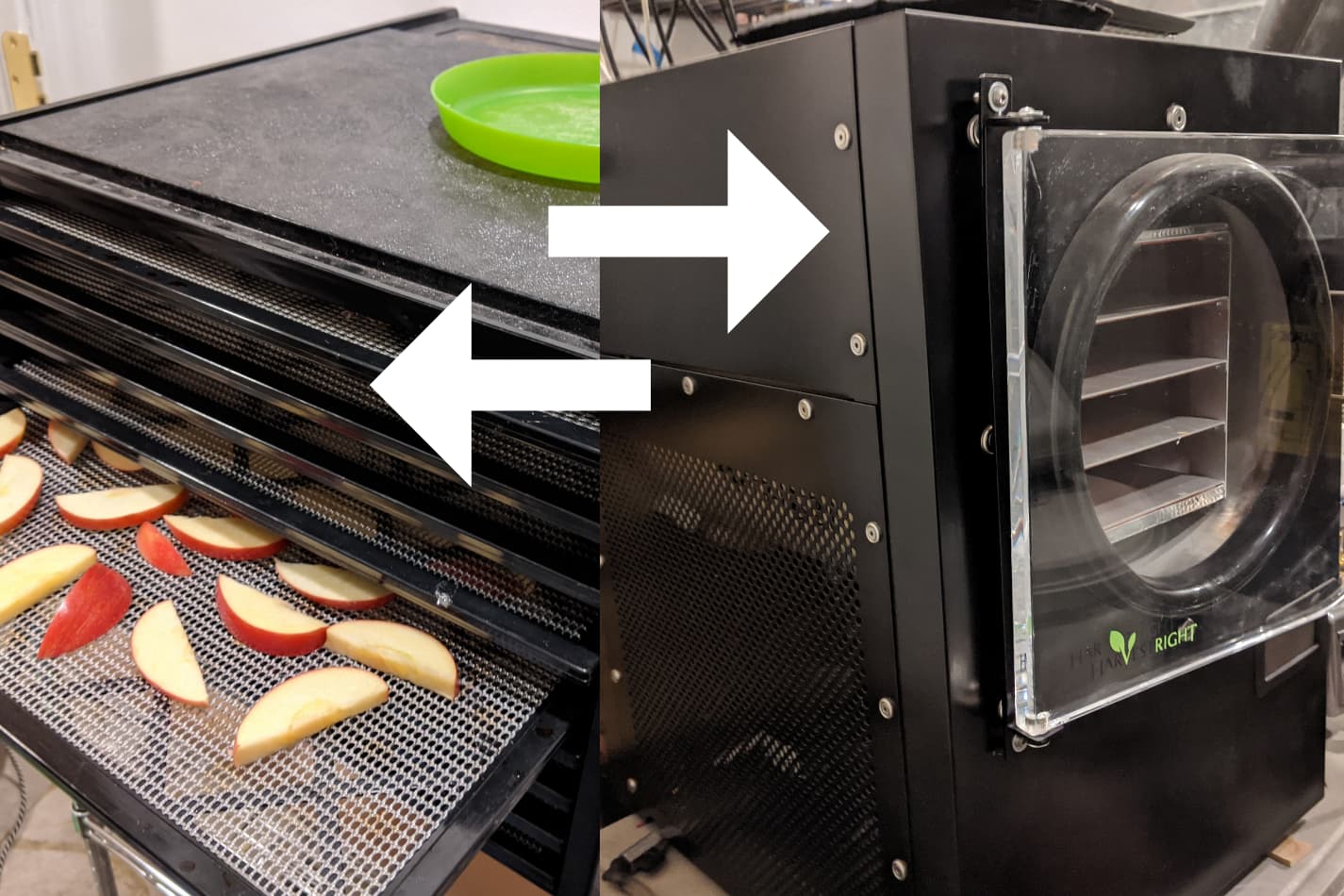

Freeze Drying vs. Dehydration

While freeze-drying and dehydrating involve removing water from food, the processes and results are quite different.

- Freeze drying uses low temperatures and a vacuum to remove moisture, preserving the food’s structure and nutritional content.

- Dehydrating uses heat and airflow to evaporate water, often resulting in a change in texture and a higher nutrient loss than freeze-drying.

While dehydrated food is lightweight and can last for a long time, it can also lose some of its flavor and nutritional value. Freeze-dried food, on the other hand, retains most of its flavor and nutrients while also being lightweight and easy to store.

Want to compare the equipment? Read my guide: Freeze Dryer Vs. Dehydrator: What’s the Difference?

Differences in Process

Dehydration and freeze-drying are different methods of preserving food by removing moisture. As someone who likes to explore various food storage techniques, I can tell you the key differences in their processes.

Dehydration involves applying heat and circulating air to evaporate the food’s moisture lightly. It’s a simpler method that has been around for centuries (if not millennia) and is quite affordable. However, dehydration may change taste and texture, potentially affecting the food’s nutritional content by up to 25% loss.

On the other hand, freeze-drying is a more advanced method involving freezing the food and placing it in a vacuum chamber. This process gradually removes moisture from the frozen food via sublimation, where it turns directly from ice to vapor. Freeze-drying effectively retains the food’s nutritional content, color, and texture while reducing weight significantly.

Results Compared

When it comes to the results of these two preservation methods, I’ve found there are a few factors worth considering:

- Shelf Life: Freeze-dried foods generally have a longer shelf life compared to dehydrated foods. The freeze-drying process removes more moisture, allowing the food to last for years or even decades when stored properly.

- Rehydration: In my experience, freeze-dried foods rehydrate better than dehydrated foods. This is because freeze-drying preserves the food’s original structure, making it easier to return to its original form when water is added.

- Nutritional Content: While both methods successfully preserve food, freeze-drying does a better job of retaining the nutritional content of the food. Various studies have shown that freeze-dried foods are superior in preserving vitamins and minerals compared to their dehydrated counterparts.

- Texture and Taste: I’ve observed that freeze-dried foods preserve their texture and taste better than dehydrated foods. Dehydrated foods can sometimes become chewy or harder in texture due to the heat used in the dehydration process.

So, while dehydration may be more cost-effective and easier to do at home, freeze-drying offers better results in terms of shelf life, rehydration, and preservation of nutritional content, taste, and texture. Both methods have advantages, and understanding the differences can help you choose the right method for your food storage needs.

Freeze Drying vs. Freezing

Freezing food stores foods below freezing (32°F) for up to several years, while freeze-drying foods remove the water so it’s shelf-stable for up to 25 years. Freeze drying causes less damage to the food’s cellular structure than freezing.

- Freezing is simply a process that preserves food at a below-freezing temperature.

- Freeze-drying removes the moisture from the food through sublimation.

Freeze drying is more effective than freezing in preserving the food’s quality because it eliminates the risk of ice crystals forming, which can damage the food’s structure and texture. Freeze drying extends the shelf life of the food while still retaining its nutritional value, which makes it quite popular in the food industry.

While freezing can be effective, it can also cause freezer burn and can only preserve food for a limited amount of time. Freeze-dried food, on the other hand, can last for years without losing its quality, making it an excellent option for those who want to create long-lasting emergency food supplies.

Differences in Process

- Freezing involves lowering food temperature to below the freezing point of water to preserve it. It’s a straightforward process, but it can cause some changes to the cellular structure of the food.

- Freeze drying is a more intricate process that removes water from the food through sublimation. This means the ice in the food turns directly from a solid to vapor without passing through the liquid phase.

Results Compared

There are a few key differences in the final results of freezing and freeze-drying that I’ve observed:

- Shelf Life: Freeze-dried foods have a longer shelf life than frozen foods because of the removal of water during the process. This makes it great for long-term storage and emergencies.

- Weight: Freeze-dried food is lightweight since the water content is removed. It’s a popular choice for backpackers, campers, and those who need portable meals.

- Taste and Nutrient Retention: Freeze-dried food often retains its flavor and nutrients better than frozen food because of the minimal damage caused during the process.

In conclusion, freezing and freeze-drying are effective food preservation methods, but they differ. I hope you found these insights helpful in understanding these two methods’ key differences and outcomes.

If you’d like to read more about freeze-drying versus freezing, read our guide here: Freeze Dryer VS Freezer – 7 Differences That Matter.

Freeze Drying vs. Canning

Canning food stores foods at room temperature for up to several years. Freeze-drying foods removes the water so it’s shelf-stable for up to 25 years. Freeze-dried foods are more like their original version than canned foods.

Canning is another popular food preservation method that involves heating food in jars to kill bacteria and sealing them to create an airtight environment. While canning can be effective, it requires a lot of time and effort, and the resulting food can lose some of its nutritional value. In contrast, freeze-dried food retains most of its flavor and nutrients, making it an excellent option for those who want to preserve their food without sacrificing quality.

Differences in Process

Freeze drying involves freezing the food and then using a vacuum to remove the water content. This process preserves the food’s flavor, nutrients, and texture without adding any preservatives. The food can then be rehydrated by adding water when it’s time to eat. I’ve found this method fascinating as it extends the food’s shelf life up to 25 years without losing its taste and nutrients.

On the other hand, canning is an older method in which food is cooked and sealed in airtight jars. The cooking process destroys any bacteria, but unlike freeze-drying, it can change the texture and flavor of the food. Canned goods typically have a few years of shelf life but not as long as freeze-dried goods.

Results Compared

I’ve noticed that freeze-dried and canned foods have some differences in their final results. Freeze-dried foods are lightweight, easy to store, and their preservation process retains more nutrients, taste, and texture. These foods can last up to 25+ years and are rehydrated, bringing them back to their original state by adding water.

- Shelf Life: Freeze-dried foods have a longer shelf life than canned foods because of the removal of water during the process. This makes it great for long-term storage and emergencies.

- Weight: Freeze-dried food is lightweight since the water content is removed. It’s popular for backpackers, campers, and those needing portable meals.

- Taste and Nutrient Retention: Freeze-dried food often retains its flavor and nutrients better than frozen food because of the minimal damage caused during the process.

On the flip side, canned foods have a shorter shelf life, and their taste and texture can be altered due to the cooking process. However, these foods are still a convenient option for preservation and are readily available in most grocery stores. The process is familiar to most people and doesn’t require special equipment like freeze-drying.

Both freeze-drying and canning have their benefits and limitations, and they can be suitable methods for different types of food. While freeze drying is a newer method that offers longer shelf life and better preservation of nutrients and taste, canning remains a reliable classic that has stood the test of time.

Safety Measures in Freeze Drying

As a freeze-drying enthusiast, I always prioritize safety while handling food so it’s safe to eat. I follow a few crucial steps to ensure food safety and prevent harm and foodborne illnesses to myself or others during and after the freeze-drying process.

First and foremost, I make it a point to maintain an optimal room temperature between 45°-75°F (7°-23°C) during freeze drying, as recommended by Penn State Extension. This temperature range promotes proper freezing and drying, safeguarding the food from harmful bacteria growth.

To further inhibit the growth of bacteria, I always use oxygen absorbers when packaging freeze-dried food. Oxygen absorbers remove any residual oxygen in the package, creating an unfriendly environment for bacteria. This helps maintain the food’s quality and prolong its shelf life.

During freeze-drying, keeping an eye on the vacuum pump is essential. Some pumps use oil that requires filtration, while others are oil-free. I use an automatically filtered oil-based vacuum pump to reduce the risk of food contamination and minimize maintenance needs (see my DIY filtration system setup here).

Following a proper cleaning routine is another vital aspect of food safety. I ensure that my freeze dryer’s chamber and trays are cleaned regularly to avoid cross-contamination and germs accumulation. Always check for etched chamber lids to ensure the proper functioning of the freeze dryer and avoid any safety risks.

Using proper safety measures adds to the effectiveness of freeze drying, ensuring food safety and enhancing the quality of preserved products. Maintain an appropriate room temperature, use oxygen absorbers for packaging, choose a suitable vacuum pump, and follow a regular cleaning routine to enjoy safe and delicious freeze-dried food.

Frequently Asked Questions

We’re here to help! Check out our FAQs section below for answers to common questions. If we missed yours, let us know, and we’ll update the article. Contact us through our website, and we’ll respond directly to your question.

How do you freeze dry at home?

Freeze-drying at home requires a freeze-drying unit. Harvest Right is the #1 brand, and the unit comes with instructions, or we’ve got how-to tutorials on this site.

What are the main advantages of freeze-drying?

Freeze drying has several benefits, including extended shelf life and preserving food’s nutritional value, structure, color, and taste. Moreover, freeze-dried food is lightweight and easy to transport, making it a popular choice for backpackers and those preparing for emergencies.

What are the disadvantages of freeze-drying?

Some drawbacks of freeze drying include the initial cost of purchasing a freeze dryer and the time-consuming process, which can take several hours to days, depending on the type and quantity of food being dried. In addition, some foods may not freeze dry as effectively as others, limiting the variety of options. Read our Best Foods to Freeze Dry: Home Freeze Dried Food Guide.

How do you freeze dry without a machine?

Freeze-drying without a machine isn’t possible, although you can freeze foods and then put them into a vacuum chamber to remove as much water as possible via sublimation. The results won’t be as good as properly freeze-drying, though.

Are freeze dryers worth it?

The value of a freeze dryer depends on your individual needs. If you’re looking for a long-term solution to food storage, freeze-drying may be a worthwhile investment, especially if you need to control the food ingredients or types. The cost savings of freeze-drying your own food compared to purchasing prepackaged emergency preparedness food can be significant in the long run. However, it’s important to weigh the initial cost and maintenance requirements against your specific needs before making a decision.

What is the optimal temperature for freeze drying?

In freeze-drying, the optimal temperature usually ranges between -30 to -50°F or lower. This low temperature helps preserve the food by removing the water content without damaging the nutrients or altering the texture, color, and taste.

Resources

Learning from your own experience is essential, but learning from others is also intelligent. These are the sources used in this article and our research to be more informed as homesteaders.

- Freeze-drying food. (n.d.). UMN Extension. https://extension.umn.edu/preserving-and-preparing/freeze-drying-food

- Freeze-Drying Fundamentals – IFT.org. (2018, February 1). https://www.ift.org/news-and-publications/food-technology-magazine/issues/2018/february/columns/processing-freeze-drying-foods

- Ghalia, M. A., & Dahman, Y. (2016). Advanced nanobiomaterials in tissue engineering. In Elsevier eBooks (pp. 141–172). https://doi.org/10.1016/b978-0-323-42865-1.00006-4

- Harguindeguy, M., & Fissore, D. (2021). Temperature/end point monitoring and modelling of a batch freeze-drying process using an infrared camera. European Journal of Pharmaceutics and Biopharmaceutics, 158, 113–122. https://doi.org/10.1016/j.ejpb.2020.10.023

- Hirneisen, A., MA. (n.d.). Let’s Preserve: Freeze-Drying. https://extension.psu.edu/lets-preserve-freeze-drying

- Labconco. (n.d.). Introduction to freeze drying. Labconco. https://www.labconco.com/articles/introduction-to-freeze-drying

- Liu, Y., Zhang, Z., & Hu, L. (2021). High efficient freeze-drying technology in food industry. Critical Reviews in Food Science and Nutrition, 62(12), 3370–3388. https://doi.org/10.1080/10408398.2020.1865261

- Mba, A. L. B. (2022, July 20). How does Freeze-Drying work and are Freeze-Dried foods healthy? Healthline. https://www.healthline.com/nutrition/freeze-drying

- Nail, S. L., Tchessalov, S., Shalaev, E., Ganguly, A., Renzi, E., Dimarco, F., Wegiel, L. A., Ferris, S. J., Kessler, W. J., Pikal, M. J., Sacha, G., Alexeenko, A., Thompson, T. N., Reiter, C., Searles, J. A., & Coiteux, P. (2017). Recommended Best Practices for Process Monitoring Instrumentation in Pharmaceutical freeze drying—2017. Aaps Pharmscitech, 18(7), 2379–2393. https://doi.org/10.1208/s12249-017-0733-1

- Pisano, R. (2020). Automatic control of a freeze-drying process: Detection of the end point of primary drying. Drying Technology, 40(1), 140–157. https://doi.org/10.1080/07373937.2020.1774891

- Prosapio, V., & Lopez-Quiroga, E. (2020). Freeze-Drying technology in foods. Foods, 9(7), 920. https://doi.org/10.3390/foods9070920

- Right, H. (2020). Six Frequently Asked Questions about the Harvest Right Freeze Dryer. Harvest RightTM | Home Freeze Dryers | Freeze Dried Food Storage. https://harvestright.com/blog/2020/six-frequently-asked-questions-about-the-harvest-right-freeze-dryer/

- Utah State University. (n.d.). Freeze drying. USU. https://extension.usu.edu/preserve-the-harvest/freeze-drying

- Utah State University. (2022, February 28). Freeze drying: Essential and nice-to-have tools and supplies. USU. https://extension.usu.edu/preserve-the-harvest/research/freeze-drying-essential-and-nice-to-have-tools-and-supplies

- Ward, K., & Matejtschuk, P. (2020). The principles of Freeze-Drying and application of analytical technologies. In Methods in molecular biology (pp. 99–127). https://doi.org/10.1007/978-1-0716-0783-1_3

- Why- and how to Perform Batch Control During the Freeze Drying Process. (2021, June). https://www.ellab.com/. https://www.ellab.com/wp-content/uploads/2021/04/why-and-how-to-perform-batch-control-during-the-freeze-drying-process.pdf